THE DIGITAL TRANSFORMATION

UNLOCKING EFFICIENCY IN THE METALS INDUSTRY: THE DIGITAL TRANSFORMATION

Imagine a world where metal companies can predict equipment malfunctions, optimize production processes, and provide personalized customer experiences. This is the transformative power of digitalization in the metals industry, where emerging and established companies are embracing cutting-edge technologies to revolutionize their operations. From real-time data analytics driving operational efficiency to personalized solutions enhancing customer satisfaction, the potential of digitalization to reshape the metals industry is truly astounding.

INCORPORATING REAL-TIME DATA ANALYTICS FOR ENHANCED QUALITY AND SAFETY

LEVERAGING DIGITAL PROTOTYPING FOR RISK AND COST REDUCTION

OPTIMIZING SUPPLY CHAIN MANAGEMENT AND MANUFACTURING THROUGH AUTOMATION

PROMOTING ENERGY EFFICIENCY THROUGH DIGITAL TRANSFORMATION

HARNESSING DATA LAKE AND CLOUD COMPUTING FOR ENHANCE DATA INTEGRATION

IMPLEMENTING VIRTUAL REALITY FOR REMOTE WORK AND MAINTENANCE

ADDRESSING CHALLENGES AND SOLUTIONS IN THE JOURNEY OF DIGITALIZATION

Solution: Develop a comprehensive change management strategy that includes upskilling and reskilling programs. Such initiatives can help equip employees with necessary digital competencies, fostering adaptability to new technologies and roles.

Solution: Create a robust data governance framework that delineates data ownership, establishes quality standards, and outlines privacy and security protocols. Utilize data analytics tools to derive actionable insights from the data.

Solution: Implement strong cybersecurity measures, including firewalls, encryption, and intrusion detection systems. Regular security audits can also be conducted to ensure the robustness of these systems.

Solution: Perform a detailed cost-benefit analysis to assess the potential return on investment. Prioritize digital initiatives that offer the most substantial impact and align best with business objectives.

Solution: Work together with solution providers to design and implement integrated systems. It’s essential to ensure compatibility between different technologies and conduct thorough testing and pilot projects to validate interoperability.

THE FUTURE OF THE METALS INDUSTRY IN THE DIGITAL AGE

Challenges exist, but a proactive approach positions the industry to embrace digital

technology’s benefits. Together, we can unlock innovation, growth, and enhanced

efficiency in the metals industry’s future. Embrace digital transformation and seize the

opportunities of the digital age.

JHelmy&Co. Empowering Excellence, Delivering Real Impact

INTRODUCTION

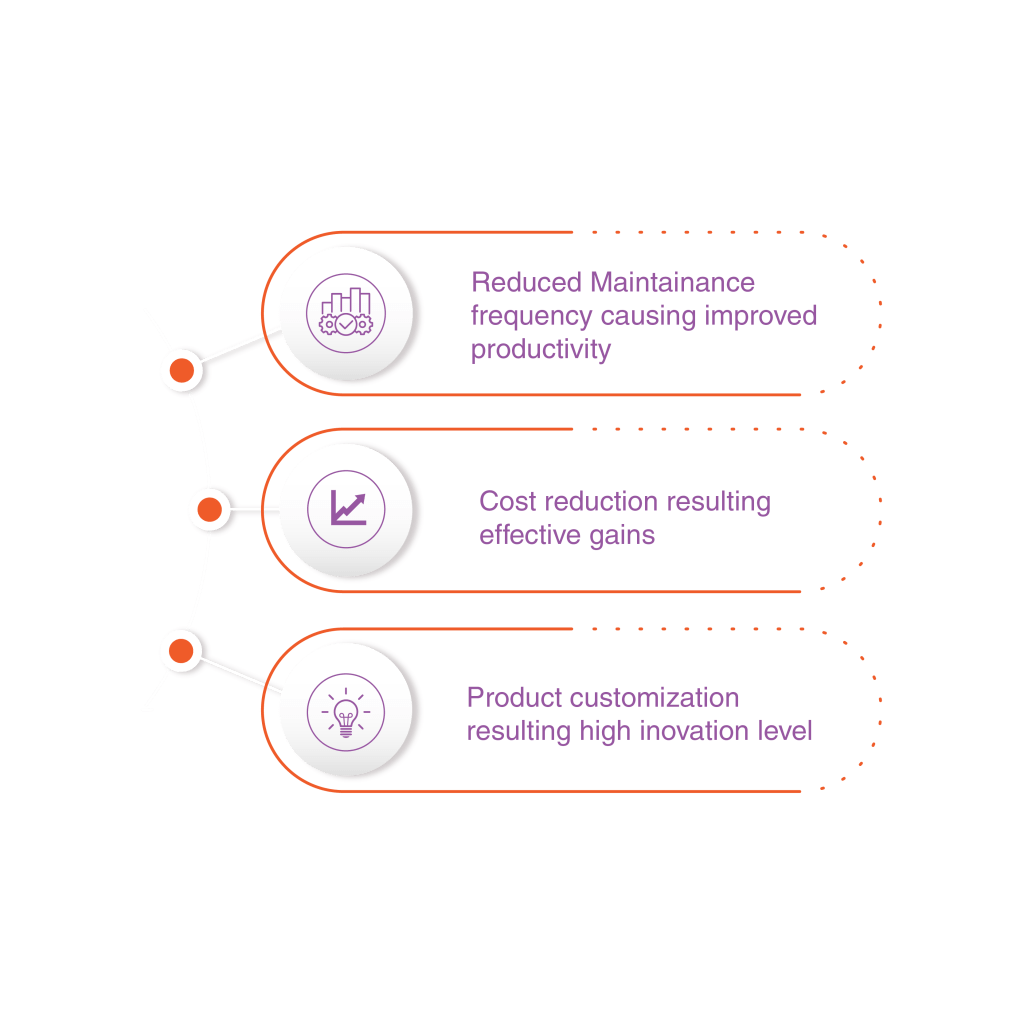

OUR DIFFERENTIATING FACTORS